The African continent is poised to become the next frontier in global steel production, with its share of world output projected to double within the next decade as international investment pours into this emerging market.

The global steel industry is undergoing its most significant transformation in decades. While attention often focuses on Asian production giants and Western decarbonization efforts, the most profound changes may well be emerging across Africa. With its abundant natural resources, growing domestic demand, and strategic position in green steel production, Africa is rapidly transforming from a steel industry bystander into a potentially transformative player in global markets.

Current African Steel Landscape: More Than Meets the Eye

While the World Steel Association officially tracks steel data from only six African nations—Algeria, Egypt, Libya, Morocco, South Africa, and Tunisia—the continent’s production footprint extends far beyond these countries. In 2024, these six countries collectively produced 23 million tons of steel, with Egypt leading as Africa’s largest producer at 10.7 million tons.

The reality of African steel production, however, is more complex than these figures suggest. Dozens of smaller-scale operations have emerged across the continent to address critical local supply gaps. Nigeria, despite having annual demand reaching 17 million tons, produces only about 220,000 tons domestically. Tanzania imports over 1 million tons of steel annually despite having domestic production capacity below 200,000 tons. This significant supply-demand imbalance represents both a substantial challenge and unprecedented opportunity for development.

Table: Major African Steel Producers (2024)

| Country | Annual Production (Million Tons) | Key Characteristics |

|---|---|---|

| Egypt | 10.7 | Africa’s largest producer, production surplus but relies on high-grade imports |

| Algeria | 4.7 | Leverages natural gas for DRI production, significant foreign investment |

| South Africa | Included in worldsteel data | Established industry facing energy challenges |

| Nigeria | 0.22 (est.) vs 17M tons demand | Massive growth potential, numerous small-scale plants |

The spatial distribution of steel production across Africa reflects broader economic patterns. Northern African countries, with their proximity to European markets and relatively developed infrastructure, have traditionally dominated production. However, sub-Saharan nations are now rapidly expanding their capabilities, often through smaller-scale, specialized facilities tailored to local market needs.

Driving Forces Behind Africa’s Steel Expansion

Infrastructure Deficit and Domestic Demand

Africa’s massive infrastructure gap is creating unprecedented demand for steel. The African Development Bank estimates annual infrastructure investment needs at approximately $170 billion, spanning transportation, energy, communications, and urban development. This demand is further amplified by regional integration initiatives that require cross-border infrastructure.

The continent’s current steel consumption patterns highlight the enormous growth potential. While global per capita steel consumption sits at approximately 219 kg, sub-Saharan Africa averages just 30 kg per capita—less than 14% of the global average. This glaring deficit represents both a development challenge and a substantial market opportunity for producers.

Strategic International Partnerships

China’s deepening involvement in Africa’s steel sector represents a strategic long-term commitment rather than mere commercial opportunism. Through its Belt and Road Initiative, China has methodically laid the groundwork for what many analysts see as a comprehensive play for both resources and influence.

Recent projects illustrate the scale and sophistication of this engagement. Zimbabwe’s Tsingshan Steel plant began production in 2024 with an initial capacity of 600,000 tons, with plans to expand to 5 million tons. Similarly, a $450 million steel manufacturing plant by China Galaxy Group and RSIN Group’s subsidiary Stellar Steel Ltd is scheduled to begin operations in Nigeria in mid-2026.

This investment extends beyond mere production facilities. Chinese companies are also transferring knowledge and building local capacity. As one Chinese steel executive noted, successful internationalization requires “localizing talent”—a lesson learned from foreign companies that have thrived in China itself.

The Simandou Effect: Reshaping Global Iron Ore Markets

The recent commencement of operations at Guinea’s Simandou iron ore project represents what some analysts term a “Pilbara killer,” referring to its potential to challenge Australia’s dominance in the global iron ore trade.

This project, dormant for nearly 30 years, is extraordinary in both scale and logistics. To access the remote deposit, developers constructed a 650-kilometer heavy-duty railway connecting the mine to a new port at Morebaya. The consortium includes industry giants: Singapore’s Winning International Group, China Baowu Steel Group (the world’s largest steel producer), Rio Tinto, and Aluminum Corp. of China, with the Guinean government retaining a 15% stake.

Simandou’s significance extends beyond volume. Its high-grade, low-impurity ore (averaging 65-67% iron content) is particularly suited for efficient steelmaking with lower emissions—a critical advantage as carbon constraints tighten globally. As shipments ramp up toward the planned annual production of 1.2 billion tons, the project is expected to substantially increase market competition, potentially lowering global iron ore prices.

Perhaps more significantly, Simandou represents a new paradigm in resource development. The “resource-infrastructure package” approach—where developers not only extract resources but also build accompanying infrastructure—creates more value for host countries while securing supply chains for developers. This model is already being studied by other resource-rich African nations seeking to avoid the “resource curse”.

The Green Steel Revolution: Africa’s Unexpected Advantage

Africa is unexpectedly emerging as a potential leader in green steel production, leveraging its abundant renewable resources rather than playing catch-up with established industrial powers. This advantage stems from both necessity and opportunity—many African nations lack conventional energy infrastructure but possess exceptional solar, hydro, and wind resources.

Several projects already demonstrate this potential. Kenya’s 500,000-ton electric arc furnace steel project operates entirely on solar power, with emissions at just one-quarter of traditional African small-scale plants. The facility’s integrated scrap recycling system processes end-of-life vehicles, contributing to a circular economy model while producing steel at prices 18% below imported equivalents.

Namibia offers another compelling case study in transformational green steel development. Facing high unemployment and energy dependency, the country has developed an innovative blueprint for green industrialization centered around a solar-powered direct reduced iron facility. This project exemplifies what Namibian officials call a “United Nations effort,” with equipment from China, technology from Germany, capital from Europe, and offtake agreements from Japan, all leveraging Namibian labor and abundant sunshine.

Table: Africa’s Green Steel Advantages

| Advantage | Application in Steel Production | Example Countries |

|---|---|---|

| Abundant Solar Resources | Powering electrolyzers for hydrogen production | Namibia, Botswana |

| High-Quality Iron Ore | Low-impurity feedstock requiring less processing | Guinea (Simandou), South Africa |

| Strategic Port Locations | Cost-effective export routes to Europe and Asia | Egypt, Morocco, South Africa |

| Growing Domestic Demand | Reduced transportation emissions for local markets | Nigeria, Ethiopia, Tanzania |

Technological Transformation and Production Methods

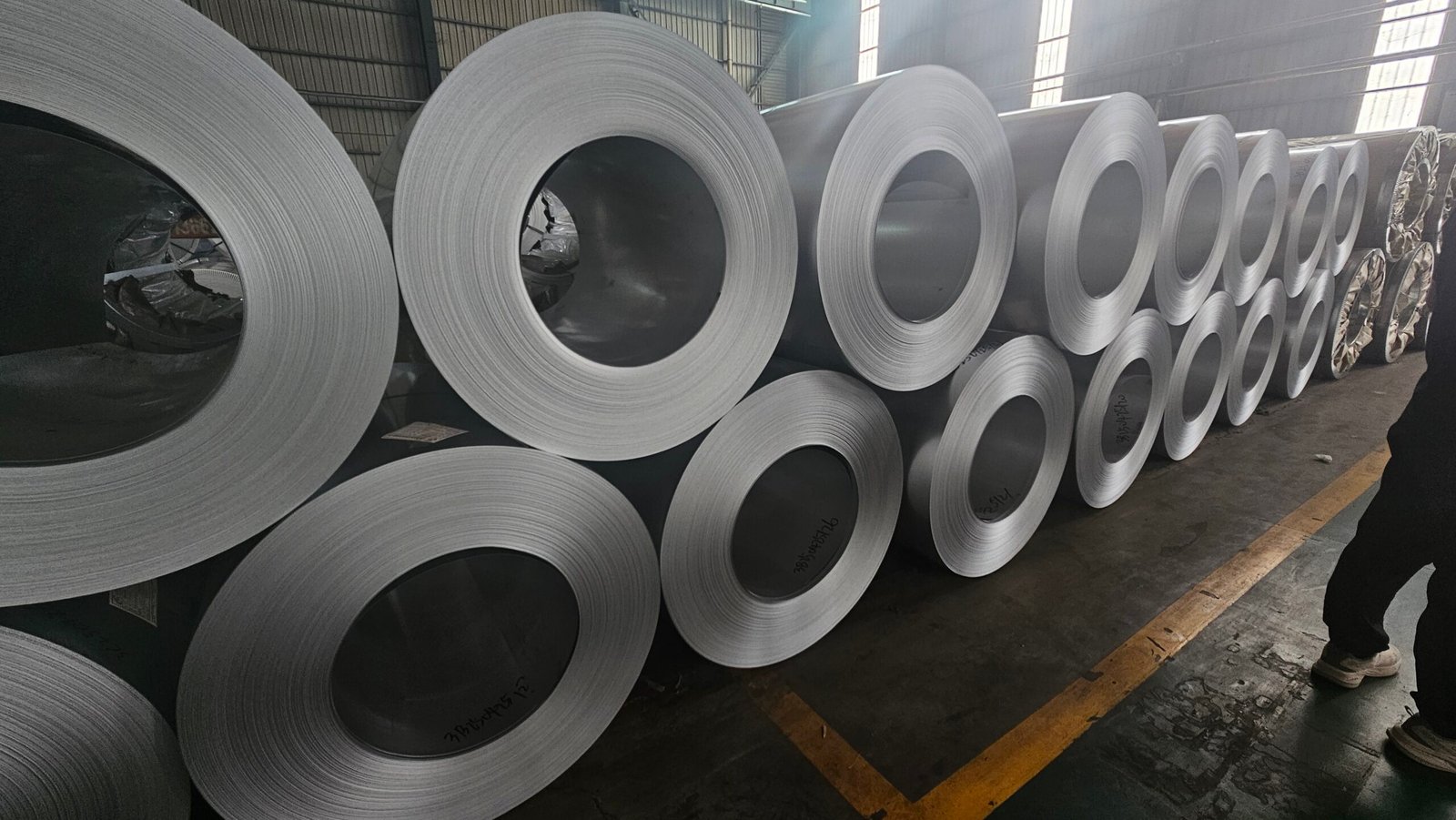

The technological landscape of African steel production is diversifying rapidly. While the traditional blast furnace route remains important, newer facilities increasingly adopt electric arc furnace (EAF) technology, often fed by direct reduced iron (DRI) processes. This approach offers several advantages in the African context: lower capital requirements, flexibility in scale, and better environmental performance when powered by renewable energy.

The trend toward more sophisticated production methods reflects both market demands and environmental considerations. Egypt’s Suez Steel recently started up an 800,000-ton heavy section mill, becoming the first producer of 54E rails in Egypt and the Middle East. Similarly, Algeria has leveraged its natural gas resources to develop significant DRI-EAF based production capacity in partnership with Turkish and Qatari companies.

According to World Steel Association General Secretary Edwin Basson, the global steel industry is evolving toward three parallel technological pathways: the traditional scrap-EAF route, gas/hydrogen-DRI-EAF systems, and greener BF-BOF processes. Africa’s emerging production infrastructure positions it well to capitalize on the second pathway, particularly in regions with abundant natural gas or renewable energy for hydrogen production.

Challenges on the Horizon

Despite the promising outlook, significant hurdles remain for Africa’s steel sector. Policy uncertainty continues to concern investors, with some countries implementing protective measures like Tanzania’s recent tightening of mining rules to favor local companies.

Infrastructure gaps—particularly in energy and transportation—constrain growth across much of the continent. While Kenya has made significant strides in electricity generation, such reliability remains the exception rather than the norm in many African nations. The skills gap also presents challenges, with technical training programs struggling to keep pace with industry expansion.

Environmental considerations present another complex challenge. Many small-scale operations that have emerged to address local supply gaps operate with limited environmental controls. In Egypt’s Alexandria region, home to 200 small steel plants, PM2.5 concentrations consistently exceed healthy limits by up to five times. Balancing environmental protection with development needs remains an ongoing challenge.

Global Market Implications

Africa’s steel rise carries profound implications for global markets. The continent’s combination of low production costs, high-quality raw materials, and proximity to major markets positions it as a potentially disruptive force in global steel trade.

The emergence of Africa as a significant steel producer comes as global demand patterns shift. While developed markets have seen stagnant or declining consumption, emerging economies—particularly in Africa and Southeast Asia—are experiencing robust growth. ASEAN nations saw steel demand reach 81.2 million tons in 2024, an 8% year-on-year increase.

This geographic rebalancing is prompting a strategic rethink among major producers. As建龙集团 Chairman Zhang Zhixiang noted, “In the next 5-10 years, major changes will take place in global steel distribution, product structure, and green manufacturing” with particular growth expected in India, the Middle East, and Africa.

Future Outlook: An Evolving Continental Role

Looking ahead, Africa’s role in global steel markets will likely evolve along multiple dimensions. The continent is poised to become not only a significant consumer as industrialization advances, but also an increasingly important producer and potentially a major exporter of both raw materials and finished steel products.

According to World Steel Association projections, global steel demand will grow moderately over the coming decades, reaching approximately 2.2-2.4 billion tons by 2050. Africa is expected to account for a disproportionate share of this growth, potentially reaching 100 million tons of annual demand by 2030.

This growth will likely be accompanied by continued regional specialization. North Africa may increasingly focus on serving European markets, particularly as carbon border adjustments make green steel production more competitive. Meanwhile, sub-Saharan Africa may develop more integrated regional value chains, processing local raw materials for regional consumption.

Conclusion: A Continent forging Its Future

Africa’s steel industry stands at a tipping point, with the convergence of infrastructure demand, strategic foreign investment, and unique green energy advantages positioning the continent as the industry’s next growth frontier. While challenges around policy, infrastructure, and skills remain substantial, the direction of travel is clear.

As Basson optimistically concludes, “We can reasonably expect that the future of the steel industry will be full of opportunities and yield fruitful results. I firmly believe that the steel industry can not only overcome these difficulties but will continue to grow and develop better”.

For global markets, Africa’s rise represents both disruption and opportunity—new sources of supply, new demand centers, and potentially, new pathways to a lower-carbon steel industry. The transformation will not happen overnight, but the foundations are being laid today across Africa’s emerging industrial landscape, promising to reshape global steel markets for decades to come.